Nickel Metal Anodes

Palm Commodities Nickel Metal has been supplied to the surface finishing industry with "total customer satisfaction" as our primary goal. Palm maintains significant nickel metal inventories assuring our loyal customer base of limited major supply chain interruptions.

Request Information

Depolarized ® Nickel Bars

Palm's Depolarized ® Nickel Bar is a unique form of 99.75 % pure nickel metal designed for the surface finishing industry. Palm's DNB does not require the use of titanium anode baskets. The special oval shape (3" x 1" oval x up to 10 ft - 1.12 lb/in) allows for drilling and tapping designed for threaded hooks or fasteners. The DNB can be used as the primary nickel source in Woods Nickel Strike, Sulfamate Nickel, Watts Nickel solutions or as auxiliary anodes for unique part types or special equipment configurations. DNB dissolves uniformly with the use of chlorides or bromides. The use of anode bags are recommended.

Electrolytic Nickel 1 x 1 Anodes

Palm's Electrolytic Nickel 1 x 1 anodes are 99.9 % high purity non-active form of nickel ideally suited for electroplating processes. Nickel squares dissolve completely in the presence of chloride in the electroplating solution leaving very little residue to accumulate. Electrolytic Nickel 1 x 1 conforms to ASTM B-39 and ISO Standard 6283.

Nickel Anodes

Distributor of nickel anodes for multipurpose nickel electroplating applications. Multiple forms and sizes of rounds, buttons, pellets, chips, plate, squares and bars. Packaged in bags, boxes, drums or super sacks.

Vale Nickel Plating Chips ®

Vale Nickel Plating Chips ® are a disk like shaped, non-activated, 99.98 % high purity form of nickel anode material made from Vale's unique carbonyl refining process. The dissolution characteristics are similar to other non-activated nickel anodes and they will dissolve at 100 % anode efficiency in common nickel electroplating solutions that contain chlorides. Dissolution produces a small amount of metallic residues.

Vale Nickel P-Pellets ®

Vale P-Pellets ® are 99.98 % high purity, non-activated plating grade nickel. The spherical pellets are produced through carbonyl refining, which is well known for producing the highest purity form of surface finishing nickel anode available. Vale P-Pellets® are screened to remove over and under-sized anode sphere's. Chlorides must be present in the plating bath for this material to dissolve efficiently. Size range is 8 to 12 mm with a packing density of approximately 5.4 to 6 kg/dm3 (0.2-0.22 lbs/in3) of basket capacity.

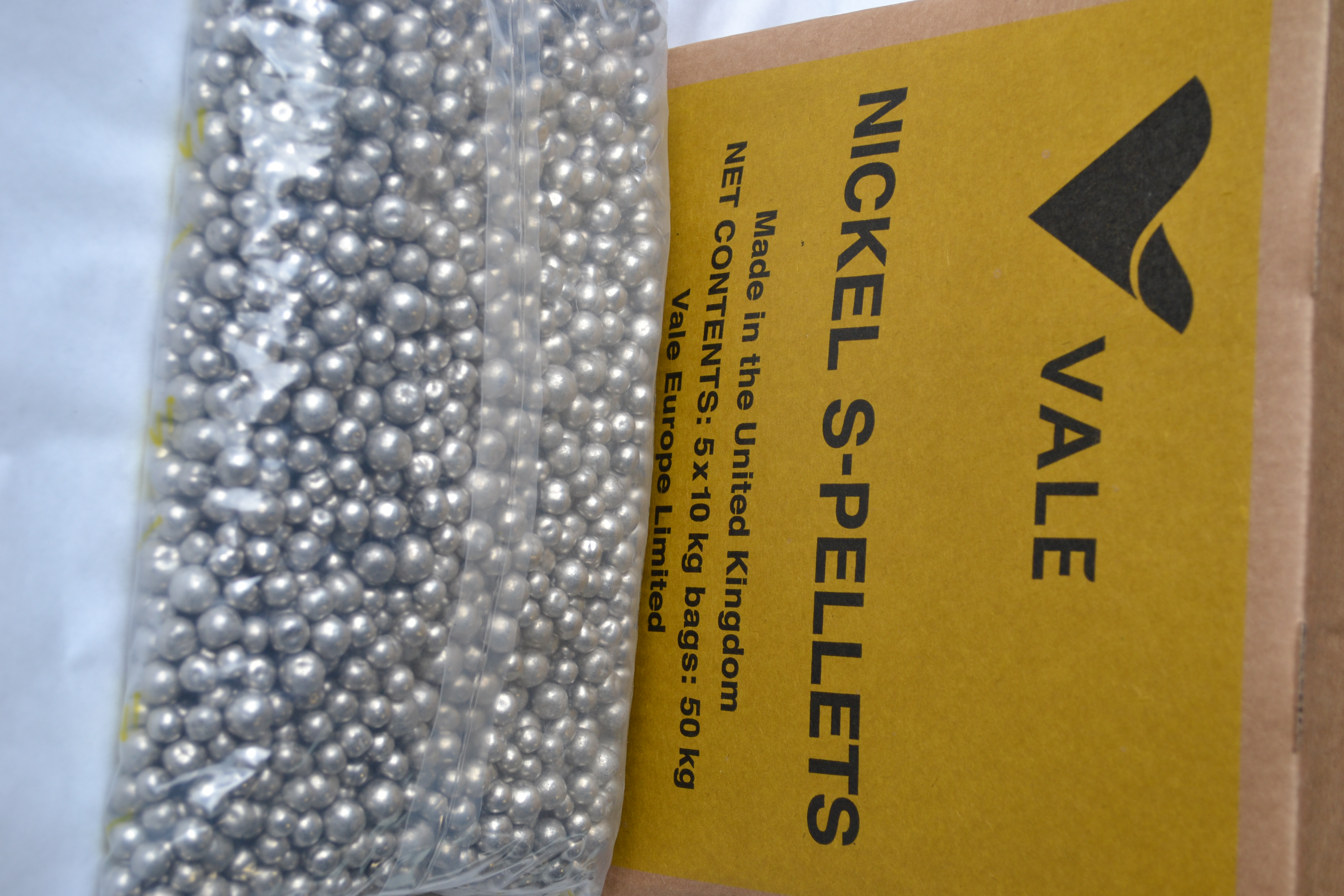

Vale Nickel S-Pellets ®

Vale S-Pellets ® are 99.96 % high purity, sulfur activated plating grade nickel. The spherical pellets are produced through carbonyl refining, which is well known for producing the highest purity form of surface finishing nickel anode available. Vale S-Pellets® are screened to remove over and under-sized anode sphere's. Lower chlorides/bromides in the plating bath are recommended for this material to dissolve efficiently. The sulfur in the product does not enter the solution but forms insoluble nickel sulfide that is retained in the anode bag where it acts to help remove unwanted copper impurities from the plating solution.

Vale Plating Rounds ®

Vale Plating Rounds 99.95 % pure electrolytic nickel is the world's most popular and ideal shape for non-activated anode material used for general purpose surface finishing with titanium anode baskets. The button shape prevents bridging of the material as it dissolves and helps the load settle uniformly in the basket. Vale Plating Rounds electrolytic nickel is safe to handle, with no sharp corners. Vale Plating Rounds comply with the requirements of ISO Standard 9002-94 and exceed the chemical requirements of ASTM B 39 and ISO 6283, NR 9980.